History

A Legacy of Invention

1963

Rotary vacuum distillation, the predecessor technology to Pristill’s CVD Pristiller system, was invented by Jack G. Bitterly in the early 1960s.

Jack, a brilliant inventor and polymath, was one of the first engineers hand-picked by Kelly Johnson to start the famous “Skunk Works” at Lockheed. Jack invented many new technologies relevant to space travel, and incorporated them in his pioneering Space Medicine Company which he sold to The Marquardt Corporation (TMC), a larger aerospace company, in the early 1960s. The Space Medicine Company became TMC’s Bioastronautics Department, and catapulted TMC to becoming a leader in bioastronautics capabilities. At the time, NASA needed a way to recycle water in zero gravity to enable deep space missions and Jack’s rotary vacuum distillation technology solved the problem and could recover 98% of the water from human waste.

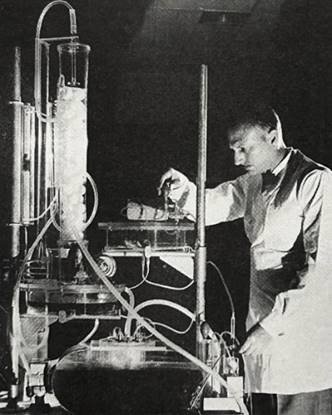

Jack Bitterly (circa 1963) working on the first water recovery system used by NASA.

1964

Jack’s Rotary Vacuum Distiller employed a rotating boiler-condenser that created sufficient g-force to keep the dirty water close to the boiler surface during evaporation. He solved the low energy requirement by recapturing the enthalpy of condensation on the opposite side of the boiler, so the machine converted contaminated water into potable water using low energy.

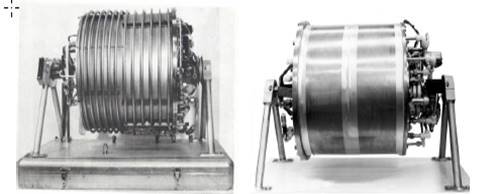

Pictures of the first rotary vacuum distiller (circa 1964). The one on the left was designed to recover water from fecal matter and urine. The second prototype on the right was designed to recover water from urine only. Both units produced 5 gals/day.

Jack Bitterly, (circa 1967), working on ECGS Astronaut Cooling System Final Test at McDonald Douglas. Picture shows a young Steve Bitterly.

1966

Following the successful tests with NASA, TMC continued to develop the water purification technology, until it was taken over by NASA and other subcontractors to be space qualified for incorporation into the International Space Station as the main workhorse urine and wastewater recycling unit. It continues to be used today.

Jack went on to work for McDonald Douglas in 1966 where he invented and developed an advanced Evaporative Cooling Garment System (ECGS) for cooling astronauts inside their hermetically sealed space suits. This invention had a cooling performance that was 10 times more efficient than the Liquid Cooling System (LCGS) that Apollo astronauts were using at the time. The ECGS was scheduled to fly to the moon and replace the LCGS system on Apollo 18, but the mission was cancelled after Apollo 17. Jack worked at McDonald Douglas until 1971 and then left to found Environmental Research Associates, to bring space-aged technologies to earthbound applications and problems.

Jack Bitterly, (circa 1968) conducting instrument check on the ECGS.

1990s

In early 90’s, Jack and his son Steve started a new venture, US Flywheel Systems (USFS). This venture was funded in part by the actor Kevin Costner, and it developed an advanced flywheel energy storage system made from spun carbon fibers, that were made to withstand the enormous tensile stresses operating up to 70,000 RPM.

By 1996, USFS became the leading and most high-tech flywheel energy storage company in the USA, selling products and services to TRW, Boeing, Honeywell, NASA and others. The venture spawned numerous new inventions including frictionless magnetic bearings and control systems, very high power-density motor-generators, and new advanced techniques for winding carbon fiber rotors.

Interest in high-specific energy flywheels as an energy storage system waned in the late 1990s following advances in lithium-ion batteries, so the technology was licensed to Moog, Inc. for advanced satellite attitude control systems.

Jack and Steve then turned their attention back to water purification.

Steve Bitterly (circa 1996) secures a flywheel casing at US Flywheel Systems

2000s

During 2000-2010, the Bitterlys improved the rotary vacuum distillation technology further and in a partnership with Cedars Sinai Medical Center in Beverly Hills, conducted tests to show the system could remove 100% of bacterial and radiological contaminants (to the limit of detection).

Extensive testing was also conducted at Sandia National Labs at Los Alamos, on the units water purification quality, conductivity and energy use..

Following a series of family tragedies, efforts to advance the technology stalled.

Centrifugal Vapor Distillation

2020

Steve Bitterly picked up the water purification project again in 2020. Using funding from NIH and DoD, he completely redesigned the original rotary vacuum distillation technology, and developed a more advanced purification system called Centrifugal Vapor Distillation or CVD.

CVD has many advancements over previous designs. It includes self-cleaning capabilities which allows the units to process more contaminated water without incurring scaling. CVD includes entirely new pumps and seals, along with other features designed to enhance purity by 10-20x. Further advances in heat transfer and blower design will deliver even greater energy efficiency.

The new CVD designs have been been patented worldwide.

2024

Formation of Pristill

In 2023, Steve reconnected with Simon Newman. The two had met in early 2000’s and remained close. Simon is a successful serial entrepreneur with a track record of starting, building, and selling technology companies, corporate turnarounds, mergers and acquisitions, and private equity investing. They decided to combine efforts.

In early 2024 a new entity and brand name was established, Pristill, Inc., which incorporated all the technology assets related to Centrifugal Vapor Distillation, including worldwide patents.

Pristill is now the platform to develop, finance, and market the water purification technologies and services developed by Steve and his father over the previous 60 years.